HP1

Vacuum filling machine

Continuous vacuum filling machine designed for linear stuffing and portioning processes, such as clipping systems. Equipped with an integrated vacuum pump with a suction capacity of 16 m³/h, it ensures efficient evacuation of the filling product. The 105-liter divided hopper with counter-support cam allows smooth product flow. A touchscreen interface provides a graphical display of all settings, functions, and error messages, with memory capacity for up to 99 filling programs. The filling performance is infinitely adjustable up to a maximum of 2,000 kg/h. The full stainless steel frame ensures durability and hygiene in demanding production environments.

Saussage Linker

Vacuum filling machine

Designed for continuous operation, this vacuum filler enables linear stuffing and precise portioning, with product evacuation handled by an integrated vacuum pump. It features a 40-liter hopper with lid and counter-support cam, a fixed and upward-orientable twisting unit, and a built-in vacuum pump with a suction capacity of 16 m³/h—ideal for both natural and artificial casings. The intuitive touchscreen displays all settings, functions, and error messages. The machine stores up to 99 filling programs, with portion weights adjustable from 1 to 99,999 grams. Depending on weight, attachments, and number of twists, it achieves portioning speeds over 350 portions per minute. The feed screw operates within a variable range of 20–570 rpm, and filling performance is continuously adjustable up to 2,000 kg/h. Built entirely in stainless steel, the machine is robust and hygienic, with no remote control interface and optimized for maximum efficiency.

HP10nx

Vacuum filling machine

The HP10nx is a continuous vacuum filling machine designed for both uninterrupted stuffing and accurate portioning. It features a robust one-piece 250-liter hopper and an integrated vacuum pump with a suction capacity of 16 m³/h, optionally upgradeable to 40 m³/h. Its centralized automatic lubrication system and stainless steel "box-in-box" electrical cabinet ensure durability and easy maintenance. A 12" touchscreen provides graphical visualization of all settings, functions, and error messages. With memory capacity for over 1,000 filling programs, the machine allows portion weights from 1 to 99,999 grams and achieves speeds of over 750 portions per minute—depending on weight, auxiliary equipment, and number of twists. Thanks to the VEMAG DuoDrive with separate drives for the feed screw and conveyor, filling output is steplessly adjustable up to 4,300 kg/h (based on a 48 mm screw pitch). It also includes a remote control interface for seamless integration with additional machines.

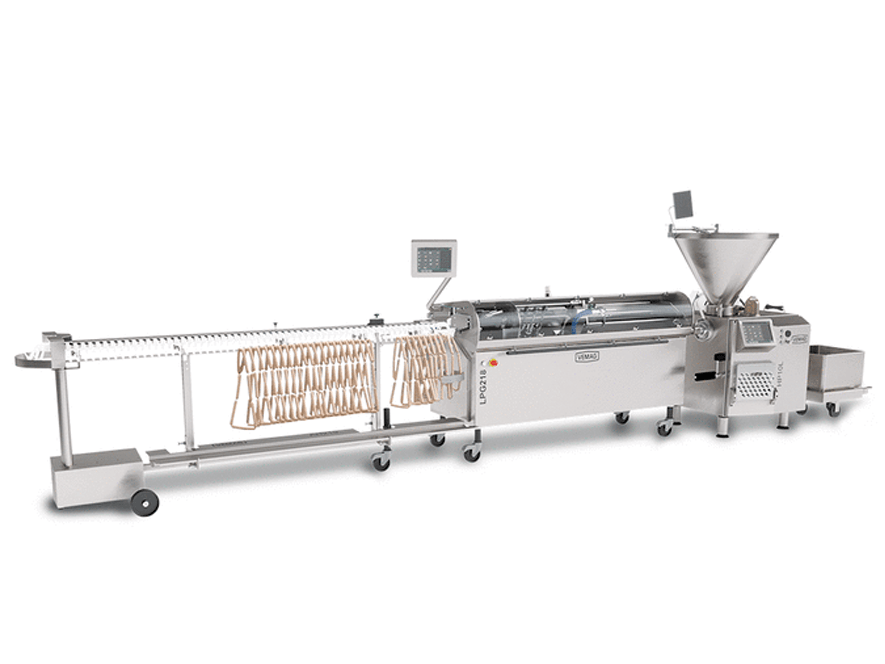

HP10NX + LPG218 + AH219

Portioning, forming, and hanging line for sausages and chorizos

The portioning, forming, and hanging line for sausages and chorizos combines precision, speed, and efficiency for continuous and profitable production. Ideal for filling into artificial casings, it offers high productivity, automatic feeding of shirred casings (up to 3 caddies), and a modular design that simplifies maintenance. The HP10nx stands out for its excellent performance, even with products like salami and mortadella closed with clips, while integration with the LPG218 and AH219 system ensures uniform products with gram-level accuracy, eliminating manual twisting and reducing the need for labor.

HP10NX + LPG208 + AH212

Continuous Stuffing and Hanging System

The VEMAG system, consisting of the HP10nx vacuum filler, LPG208 length portioner, and AH212 automatic hanging unit, is an integrated solution for industrial sausage production—ideal for products such as sausages, chorizos, and bratwursts in natural, collagen, or cellulose casings. It delivers continuous output of up to 4,300 kg/h and up to 750 portions per minute, ensuring high precision in weight and length. With double screw technology, twin-head design, and servo-driven casing loader, it enables fast casing changes, reduces product waste, and boosts efficiency. Its hygienic, easy-to-clean design and fully automated hanging process ensure reliable, profitable production with excellent product quality.