Table top machines

With single or double clip system

Polyclip manual clippers are essential tools in the food industry for the secure closing of sausages, bags, and nets. Made of stainless steel, they feature a hygienic and robust design that ensures easy cleaning and long-lasting durability. These clippers are compatible with natural, collagen, fibrous, and plastic casings, and can close products with calibers ranging from small sizes up to 120 mm. Manual operation via a lever provides a firm, ergonomic seal, with an optional integrated knife to remove excess material. Ideal for artisanal production or semi-industrial lines, Polyclip manual clippers offer an efficient and reliable solution for packaging meat products and other food items.

Semi-automatic clipping machines

Double clipping

Polyclip's semi-automatic clippers are essential equipment in the food industry for efficiently sealing sausages. These machines handle various casing types—natural, collagen, fibrous, and plastic—with capacities varying by model. For instance, the DC 600 processes natural, collagen, and fibrous casings up to 50 mm in diameter, and plastic casings up to 90 mm; the DC 700 handles natural and collagen casings up to 60 mm, and plastic casings up to 115 mm; and the PDC 700 can close all casing types with diameters up to 115 mm. These clippers feature electro-pneumatic control, ergonomic design, low air consumption, and advanced safety systems, meeting the hygiene and efficiency standards required in food production.

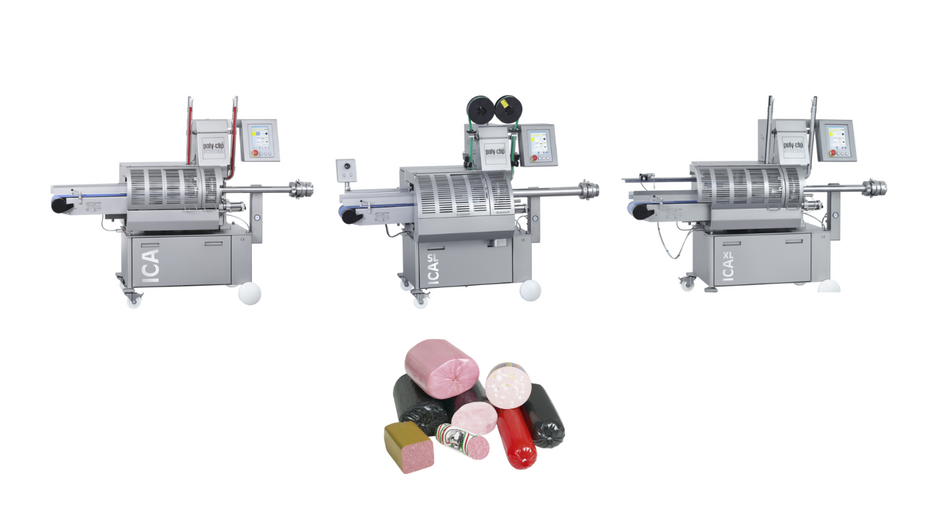

FCA series automatic clippers

Double clipping

Poly-Clip System’s automatic clippers are essential tools in the food industry, offering efficient and precise sealing solutions for various casing types and calibers. Models like the FCA 160 can close collagen casings up to 90 mm, fibrous casings up to 120 mm, and plastic casings up to 160 mm, with a capacity of up to 160 cycles per minute. The ICA is ideal for molded products up to 200 mm, handling fibrous, collagen, and plastic casings. It features an innovative iris separator for short, symmetrical ends, ensuring a clean, consistent finish. For extra-large calibers, the ICA XL processes up to 250 mm, making it suitable for casings with internal spice coatings, thanks to its gentle sealing system. These machines integrate advanced technologies that ensure tight, uniform closures while adapting to the specific requirements of each casing and product—supporting continuous production and compliance with food safety standards.

ICA series automatic clippers

Double clipping

The ICA automatic clipper is the ideal solution for large-caliber and molded products up to 250 mm, such as molded hams and slicing products even those made from whole muscle. It efficiently processes fibrous, collagen, and plastic casings, while the innovative Iris separator scissors ensure accurate separation and air-free loose filling. With an overspread of up to 300 mm and a performance of up to 60 cycles per minute in continuous mode, the ICA is a reliable and versatile choice for high-demand production environments.